When storing or transporting potentially hazardous chemicals, it is important to ensure that they are safely contained. In the context of purchasing an intermediate bulk container (more commonly known as an IBC), one of the first steps towards selecting a suitable IBC for your requirements is to check whether it is UN approved. But what does that mean?

If you are unsure about what UN approved packaging is and why it's important, take a look at our comprehensive guide to understanding it all below.

What is UN Approved packaging?

Why is UN Approved packaging important?

Does my IBC need to be UN Certified?

The UN packaging certification process

UN packaging codes

What can you store in an IBC container?

What is UN Approved Packaging?

UN approved packaging is a type of packaging which has been built, tested and certified by the United Nations to facilitate the transport and storage of dangerous goods. All packaging which has a UN certification mark has undergone a series of tests to ensure that it satisfies the UN’s standards in relation to its durability, stability and water absorption.

By successfully meeting these requirements, UN approved packaging mitigates the potential risk of releasing hazardous materials into the environment. By preventing this exposure, UN certified packaging safeguards both human and ecological safety.

Why is UN Approved Packaging Important?

UN approved packaging is important due to the risks associated with the inadequate packaging of hazardous substances. If hazardous substances which are inadequately packaged are stored or transported, there is a potential risk to human life and the environment. By using UN approved packaging, these potential threats are mitigated.

Beyond its role in ensuring health and safety, the UN certification mark is used as an identifier. The certification mark assists those in the handling of the packaging to recognise what is in the container, enabling them to take the appropriate actions.

Does my IBC need to be UN certified?

You will need to use an IBC that is UN certified if you are planning on using it to store or transport substances or materials that are potentially harmful. By using an UN approved IBC to store or transport hazardous goods you will be preventing an environmental incident from occurring. If your IBC is not UN approved and you are found to have used it to store hazardous substances, then you could be fined or even risk a prison sentence. These implications may sound harsh, however, by failing to use UN certified packaging you are risking the safety of the surrounding environment and ecosystem.

The UN Packaging Certification Process (for IBC containers)

As part of the UN packaging certification process, a variety of tests are conducted to assess whether the packaging meets the appropriate standards. For an IBC container to be UN approved, just some of the tests it must pass include:

- Bottom lift test. The bottom lift test is performed on IBCs to ensure that they can be safely lifted and transported using the bottom lifting points. As part of the test, the IBC is attached to a lifting device and is lifted above the ground using its lifting points. If the IBC is lifted and transported without deformation or leaking then the test is passed.

- Top lift test. The top lift test is performed on IBCs to ensure that they can be safely lifted and transported using the top lifting points. As part of the test, the IBC is attached to a lifting device and is lifted above the ground using its lifting points. If the IBC is lifted and transported without deformation or leaking then the test is passed.

- Stacking test. The stacking test is used to assess the maximum stacking load of IBCs. If the IBC is not deformed or has lost no contents, the test will be passed.

- Leakproofness test. The leakproofness test is performed on IBCs to ensure that there is no leakage and that they will be able to safely transport hazardous substances. To conduct this test, by filling the IBC with air and then pressurising it to a certain level. Checks are then done to assess whether the container has leaked.

- Hydrostatic pressure test. The hydrostatic pressure test checks whether the IBC can withstand the pressure of being filled with liquid. If the IBC does not leak or become deformed, the container will have passed the test.

- Drop test. The drop test assesses an IBC’s ability to withstand the impact of being dropped from height without leaking or deforming.

- Vibration test. The vibration test checks whether an IBC can withstand the vibration of being transported to ensure that it remains intact.

- Fire test. The fire test is designed to evaluate an IBC’s fire resistance to ensure that the container will not contribute to the spread of fire.

- Permeation test. The permeation test assesses the rate at which a substance can permeate its walls.

- Design qualification test. The design qualification test is used to check that the design of the IBC is compliant with safety and UN standards.

- Inspection and testing. This test is used to check that the quality of the IBC is compliant with safety and UN standards.

UN Packaging Codes (for IBC containers)

The UN packaging code, or specification mark, demonstrates that the packaging has been approved by the UN for the transportation of hazardous goods. A UN packaging code allows those handling the packaging to easily identify the characteristics of the packaging, which can dictate how they handle the packaging.

When it comes to purchasing an IBC, you don’t need to worry about finding out if your IBC has an UN certification. This is because providing that the IBC supplier has records of its UN certification, the IBC will be safe to use.

How to Read UN Packaging Codes

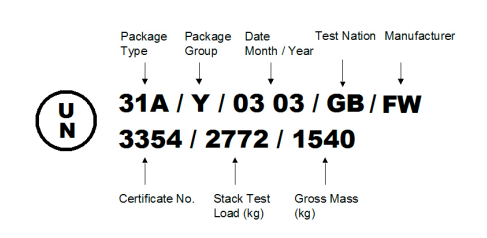

There are several sections to a UN packaging code. By assessing this UN packaging code, you will be able to find out everything you need to know about an IBC.

Here is an example of how to read a UN packaging code for an IBC:

UN Symbol

The UN symbol demonstrates that the packing has been approved by the UN. It also allows those who handle the material to easily identify and understand how it should be treated.

Package Type

The packaging type code uses numbers and letters to identify the type of container. Each number and letter is assigned to either a type of container, a container material, and a container packaging. By breaking down the string of letters and numbers you can identity the type of packaging

Package Group

The package group (also known as the hazard rating) indicates the degree of danger for the hazardous substance contained in the container.

- Extreme Hazard Group I: Pack Group X

- Moderate Hazard Group II: Pack Group Y

- Low Hazard Group III: Pack Group Z

Date of Manufacture

The date of manufacture states the month and the year when the material was manufactured, i.e. 08.23, would indicate that the material was manufactured in August 2023.

Test Nation

The test nation code is the country code where the material was tested, i.e. GB is Great Britain.

Manufacturer

The letters will inculcate the manufacturer.

Certification Number

The certification number indicates that the packaging has met the requirements.

Stack Test Load

The stack test load illustrates the results of the stack test load, this number indicates how much weight can be stacked on this container, i.e. 0 means that the container is not designed for stacking.

Gross mass

The gross mass states the maximum weight (and unit of measurement) of the package once the hazardous substance is contained within it.

What can you store in an IBC container?

Even if an IBC container is UN certified, you will still need to ensure that the substances you store or transport in it are suitable. For instance, in the case of alcoholic hand sanitiser, you will need an IBC that is not only UN approved, but also anti-static. This is because an anti-static IBC will reduce the static electricity build-up and lower the flashpoint, making it safer to transport this kind of product. Therefore, storing or transporting substances in IBCs, it is important to conduct a risk management assessment to ensure that an IBC is an appropriate solution.

Find a UN Approved IBC container with Kingfisher Direct

If you need assistance to select an UN approved IBC container that is suitable for your needs, please contact our sales team on 01777 858009 or email sales@kingfisherdirect.co.uk.